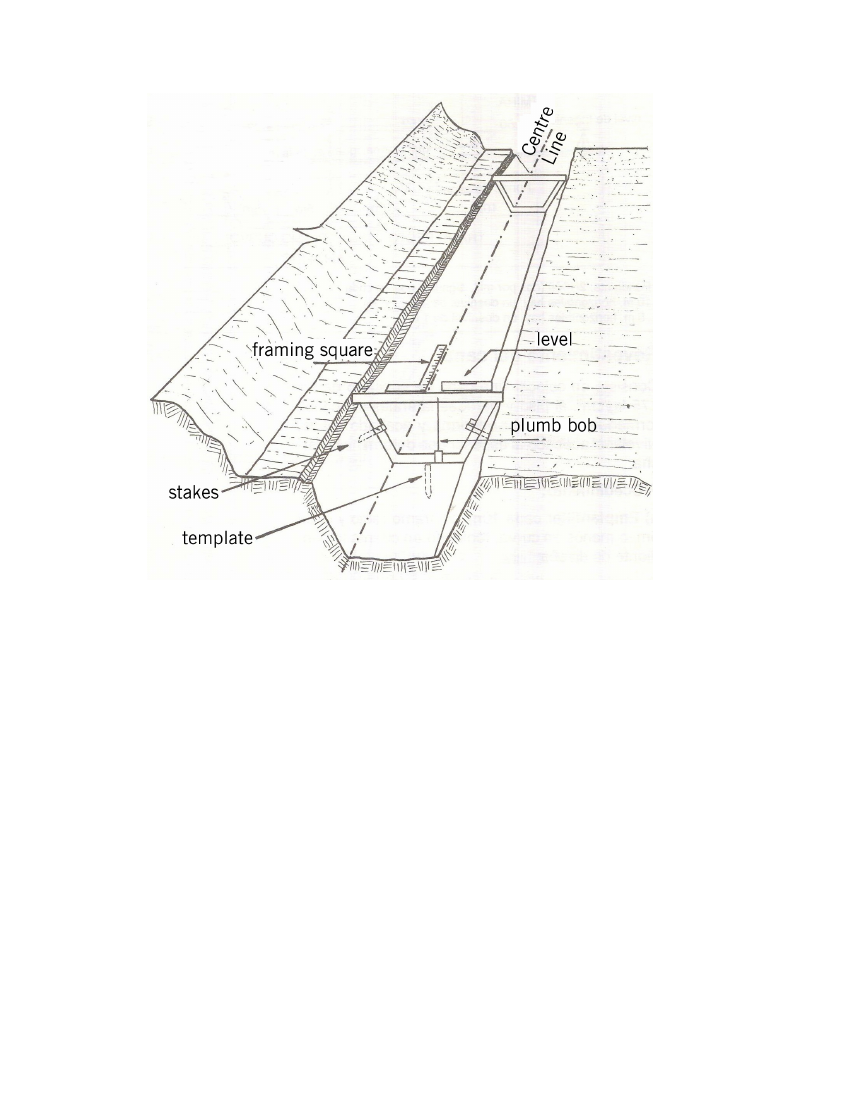

Fig. 13

c) Lining

Preparation of the mix: In volume, f'c:175 kg/cm2 is equivalent to mixing

one bag of cement, 2 wheelbarrows of sand and 3 wheelbarrows of

stones (each wheelbarrow = 1 cubic foot).

After these dry materials have been mixed and turned at least three

times, add a quantity of water, which in litres must not be more than half

the total weight of the cement (1 kg = 1 litre).

Then put mortar on the banks, compacting it with the ruler. The

hammered stakes must be removed before the final finish.

Next, sprinkle cement with fine sand 1:3 and use a pasting tool to give it

a polished and waterproof finish.

Once the banks are completed, follow the same procedure for the canal

bed.

When finishing the borders, make sure they are aligned, to which end a

ruler or rope should be used between one wooden frame and the next.

12